Machine Made Hollow Glass Magnesium Sandwich Panel

Classification :

Machine made sandwich panels

Key Words:

Machine made sandwich panels

Product Details

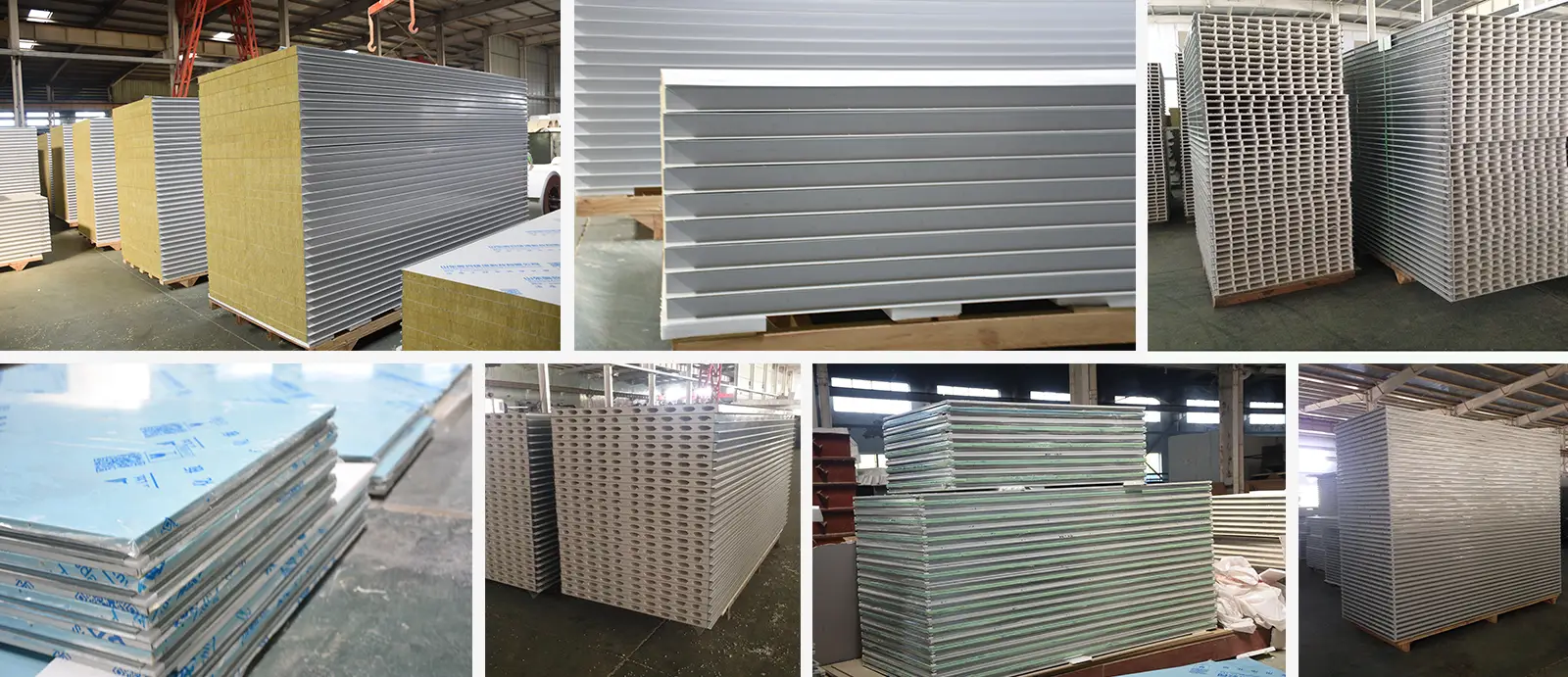

Machine made Glass Magnesium hollow composite sandwich steel panel uses color coating steel plate as the facial material, with hollow glass magnesium as the core material, and uses thermal curing glue to compose light building plates in the continuous molding machine. The glass magnesium plate is made of magnesium oxide, magnesium chloride and water triple system, and made of a stable magnesium gel material made by configuration and altering agent. New non -combustible decorative materials for filling. It is processed by special production technology, which has the characteristics of fire prevention, waterproof and tasteless, non -toxic, non -frozen, non -rotten, non -cracking, unchanged, non -combustible, high -quality light and other characteristics.

Product parameters

| Product name: Product thickness: Scope of application: |

Machine made hollow Glass Magnesium Clear Purifier 0.426-0.6mm Galvanized color coating steel plate Purifying plant ceiling, enclosure and purification product industrial plant |

||

| Product size: | Effective width of 1150mm Thick length can be customized | ||

| Panel form: Product color: Installation method: |

Hot -galvanized color coating plate is the surface layer (two layers) and thermal curing adhesive Gray (large quantity can customize other colors) Male and female mouth |

||

| Noise reduction method: | 20-30 decibel | ||

| Fire level: | A1 Grade/non -burning | ||

| Applicable features: | Use hollow glass magnesium as the core material to warm up and pressurize by high -speed continuous automation molding machine Compound, has the characteristics of high temperature resistance, flame retardant, and high toughness. |

||

equipment

The company has a modern production workshop and advanced production equipment. Its main products include purification color steel plates, medical assembled electrolytic plates, medical antibacterial electrolytic plates, medical purification steel doors, medical electric airtight doors, environmentally friendly air purification equipment, junior and middle school high-efficiency filters, laminar flow for medical operating rooms, LED purification lamps, purification hollow windows and other purification products.

Customer visit

The new era sets sail on a new journey, and new technology achieves new goals. The pursuit of excellence is the quality of Oma people, and excellence is the pattern of Oma people! Every Oma person adheres to the business philosophy of honesty, dedication and dedication, and contributes to turning grand goals into beautiful realities. The journey of the road begins with one's feet, and a new journey has begun!

Factory

The company has always served the purification plants in the food, biopharmaceutical, medical, precision instruments, optical optoelectronics, cosmetics, health care products and other industries. It mainly undertakes the design and installation of purification projects and ventilation duct projects of 100 to 1 million levels such as purification laboratories of scientific research institutions, sterile operating rooms in hospitals, infectious disease wards, PCR laboratories, laminar flow wards, negative pressure operating rooms, etc. The company has a high-quality engineering design, installation and technical supervision team.