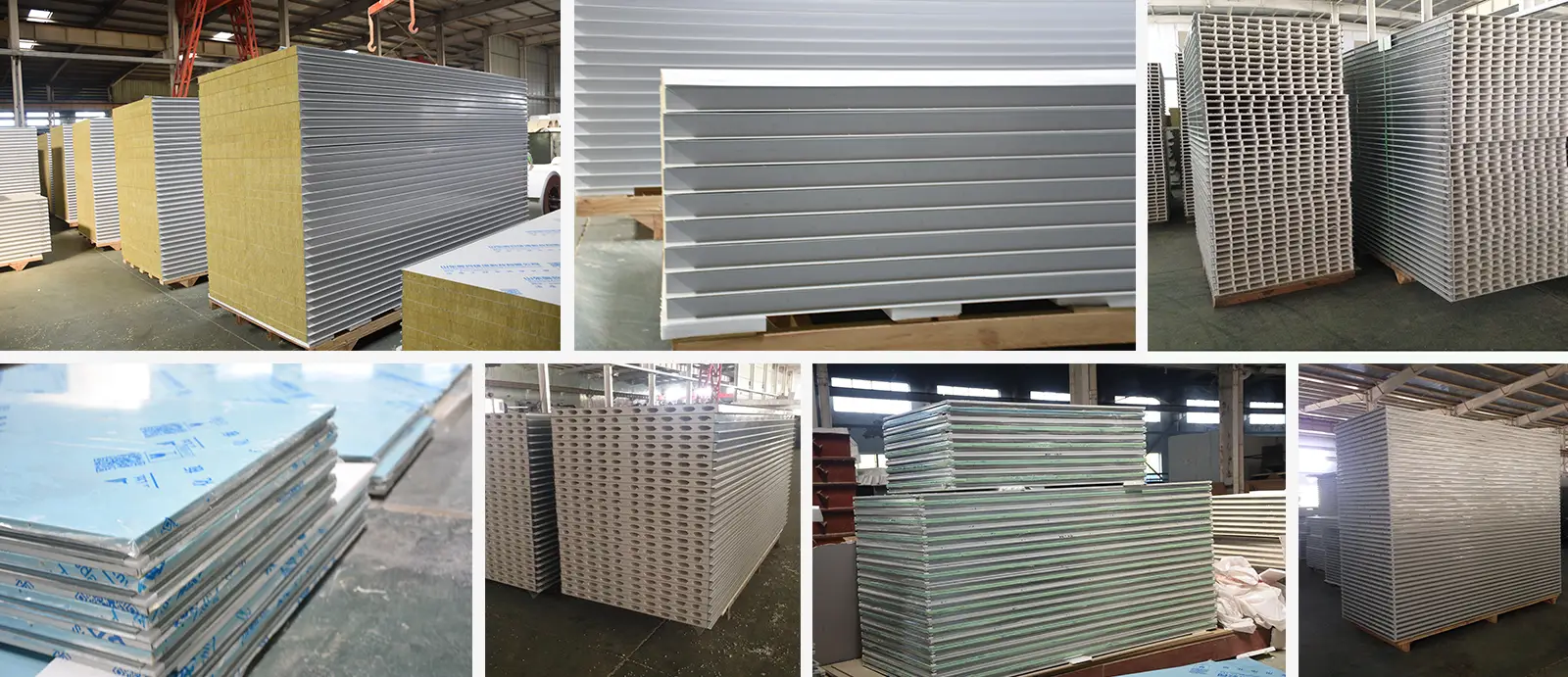

Handmade polyurethane (PU) sandwich panel

Classification :

Handmade sandwich panels

Key Words:

Handmade sandwich panels

Product Details

- Exceptional Thermal Performance

Thermal insulation is one of the polyurethane sandwich panel's most prominent attributes. The closed - cell structure of the polyurethane core serves as an outstanding barrier to heat transfer. By minimizing conduction, convection, and radiation, it effectively reduces the flow of heat through the panel. For instance, in large - scale cold storage facilities, these panels prevent the ingress of external heat, maintaining a consistently low - temperature environment inside. In residential buildings, they help in keeping the indoor temperature stable throughout the year, leading to reduced energy consumption for heating and cooling systems. - Impressive Mechanical Strength

Despite its lightweight nature, the polyurethane sandwich panel exhibits remarkable mechanical strength. The combination of the rigid polyurethane core and the robust outer facings provides excellent load - bearing capabilities. The outer metal facings, in particular, enhance the panel's resistance to bending, impact, and compressive forces. This makes it suitable for use in roofing systems where it must withstand the weight of snow, wind loads, and occasional foot traffic during maintenance. In wall applications, it can support the weight of cladding materials and provide structural integrity to the building envelope. - Superior Soundproofing Qualities

Sound insulation is another area where polyurethane sandwich panels shine. The dense polyurethane core is highly effective at absorbing sound waves. Whether it's the constant hum of traffic outside a building or the noise from adjacent rooms, these panels can significantly reduce the transmission of sound. This makes them an ideal choice for buildings such as hotels, offices, and recording studios, where a quiet indoor environment is crucial. - High Durability and Weather Resistance

Polyurethane sandwich panels are designed to endure harsh environmental conditions. The outer facings are often treated with anti - corrosion coatings, protecting them from rust and oxidation. The polyurethane core is resistant to moisture, preventing the growth of mold and mildew. This makes the panels suitable for use in coastal areas, where high humidity and salt - laden air can be corrosive, as well as in regions with extreme temperature variations. Their long - lasting durability reduces the need for frequent replacements, resulting in cost - savings over the life cycle of a building. - Diverse Applications

These panels have a wide range of applications across different sectors of the construction industry. In industrial buildings, they are commonly used for roofing and wall cladding, providing both insulation and structural support. In commercial buildings, such as shopping malls and office complexes, polyurethane sandwich panels contribute to energy - efficient design and a modern aesthetic. They are also increasingly used in residential construction, for both new builds and renovations, to improve the comfort and energy performance of homes. Additionally, they find applications in cold storage facilities, clean rooms, and pre - fabricated buildings.

equipment

The company has a modern production workshop and advanced production equipment. Its main products include purification color steel plates, medical assembled electrolytic plates, medical antibacterial electrolytic plates, medical purification steel doors, medical electric airtight doors, environmentally friendly air purification equipment, junior and middle school high-efficiency filters, laminar flow for medical operating rooms, LED purification lamps, purification hollow windows and other purification products.

Customer visit

The new era sets sail on a new journey, and new technology achieves new goals. The pursuit of excellence is the quality of Oma people, and excellence is the pattern of Oma people! Every Oma person adheres to the business philosophy of honesty, dedication and dedication, and contributes to turning grand goals into beautiful realities. The journey of the road begins with one's feet, and a new journey has begun!

Factory

The company has always served the purification plants in the food, biopharmaceutical, medical, precision instruments, optical optoelectronics, cosmetics, health care products and other industries. It mainly undertakes the design and installation of purification projects and ventilation duct projects of 100 to 1 million levels such as purification laboratories of scientific research institutions, sterile operating rooms in hospitals, infectious disease wards, PCR laboratories, laminar flow wards, negative pressure operating rooms, etc. The company has a high-quality engineering design, installation and technical supervision team.